NVIDIA has announced that US manufacturers have begun to implement NVIDIA Omniverse into robotic factories and new autonomous collaborative robots.

The announcement comes as Siemens becomes the first company to develop digital twin software that supports the Mega Omniverse Blueprint.

Currently in beta testing, the new industrial technology stack will be part of the Siemens Xcelerator platform.

It will seek to help engineers design and operate large-scale digital twins of factories that bring together realistic 3D models with live operational data.

Belden, Caterpillar, Foxconn, Lucid Motors, Toyota, TSMC and Wistron have built Omniverse factory digital twins to accelerate AI-driven manufacturing.

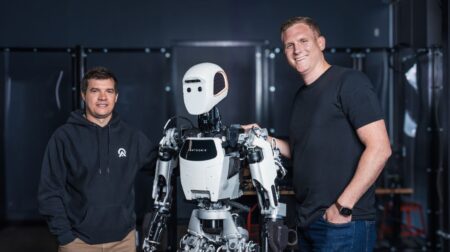

Additionally Agility Robotics, Amazon Robotics, Figure and Skild AI build America’s collaborative robot workforce using NVIDIA’s three-computer architecture.

Amazon Robotics is using Omniverse libraries and frameworks to shorten the development of Amazon’s various manipulation systems and mobile robots.

Skild AI is building a general-purpose robotics foundation model that spans legged, wheeled and humanoid robots, using Isaac Lab for locomotion and dexterous manipulation tasks training and NVIDIA Cosmos world foundation models for generating training datasets.

FieldAI is training cross-embodied robot brains for monitoring and inspection in construction and oil and gas environments, using Isaac Lab for reinforcement learning and NVIDIA Isaac Sim for synthetic data generation and software-in-the-loop validation.

Founder and CEO of NVIDIA, Jensen Huang, said: “AI is transforming the world’s factories into intelligent thinking machines – the engines of a new industrial revolution.

“Together with American’s manufacturing leaders, we’re building physical AI, Omniverse digital twins and collaborative robots that will drive productivity, resilience and competitiveness across the U.S. industrial base.”

Join us at IntraLogisteX 2026 – the USA’s leading exhibition dedicated to the future of logistics and supply chain operations. Taking place at the Kay Bailey Hutchison Convention Center in Dallas, Texas on September 16-17, 2026, the event showcases cutting-edge solutions in automation, intralogistics, supply chain technology and materials handling. Network with industry leaders, discover new technologies, and see how AI, robotics and automation are transforming performance, resilience and sustainability. Please visit www.intralogistexusa.com for more information.