CKF Systems was commissioned to install a robotic picking system featuring ABB’s IRB360 FlexPicker robots and PickMaster vision software into one of the UK’s largest food manufacturers in 2019, helping it to pick a consumable product at one of its major factories.

The system is helping the food manufacturer to produce, pack and distribute a steady supply of its product to UK supermarkets.

The system replaces a previously installed robotic picking line that used an older version of ABB’s FlexPicker, the IRB340.

Originally installed in 2008, the old line had begun to experience reliability issues caused by various hardware and software problems.

After one software issue that cost the company a substantial sum due to lost production, the decision was made in late 2017 to replace the line with a new and upgraded alternative.

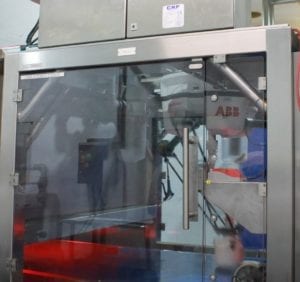

The project was awarded to CKF Systems, which installed four picking cells using ABB IRB 360 FlexPicker robots with new controllers and ABB’s PickMaster 3 vision system.

Together, this equipment ensures the product is carefully and accurately picked and arranged into stacks, ready for packing and dispatch to British supermarket shelves.

With production going into tens of thousands per day, the client was keen to minimise the time needed to get the new system installed and operational.

For this reason, CKF had just 15 days to install, test and commission the complete system prior to the picking process resuming.

“Obviously, you always want to try to get as much time as possible for projects like these, especially where you’ve got a fragile product, which presents a high risk of breakage,” says Elliott Grice, project engineer for CKF Systems.

“But the fact that we had planned everything in advance and devoted extra resources to the install helped ensure that the system was able to be installed, tested and made operational in time for the client’s two-week deadline.”

The new system started operating in 2019. With two IRB 360 FlexPicker robots serving the left side of the conveyor and two handling the right, the product is sucked into vacuum pods on the end of each robot arm, which retain them until a stack of four has been achieved.

The position of each product is detected by the PickMaster software, which accurately identifies their location on the conveyor belt.

When a stack of four has been collected, the robots deposit them on to separate conveyors that run to the packing line.

From here they are combined into a stack of eight before being manually packed into plastic trays, which are then sealed and sent for dispatch.

To help minimise the risk of breakage and consequent wastage during the picking process, the timing of the suction tool was carefully fine-tuned to ensure cycle time was as short as possible of the FlexPicker’s vacuum pods.

The PickMaster vision system is also programmed to reject any product that does not meet the correct size and shape specification, or which are overlapping and may not be cooked properly.

Running 24 hours a day from Sunday to Friday, the FlexPicker robots handle up to 400 picks per minute, enabling the customer to produce a throughput of 250,000 per day.