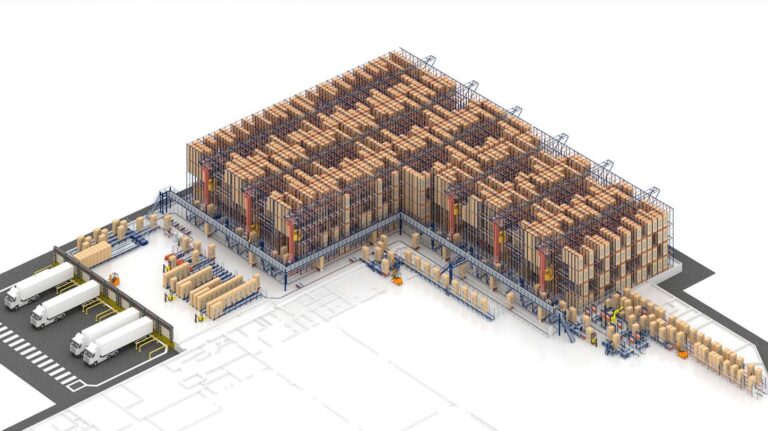

PepsiCo has announced plans to open a new automated storage and retrieval system (AS/RS) in Grodzisk Mazowiecki, Poland.

The smart warehouse would open in the third quarter of 2026 and feature six stacker cranes serving racking equipped with the Automated Pallet Shuttle.

A floor-mounted electric monorail system and automatic conveyors will link the warehouse with the production lines, enabling a continuous, round-the-clock pallet inflow.

AS/RS operations will be overseen by Mecalux’s Easy WMS warehouse management system, which will be integrated with PepsiCo’s SAP eWM software.

This two-way connection will coordinate all logistics processes, from goods receipt to outbound shipments.

This AS/RS will be the third warehouse project Mecalux has delivered for PepsiCo Polska.

Additionally, the Grodzisk Mazowiecki facility’s stacker cranes equipped with an energy recovery system estimated to save between 15% and 20% in energy consumption with every movement.

They also incorporate an AI-powered computer vision system instead of traditional photocells, ensuring safe, accurate pallet positioning.

PepsiCo warehouse automation design manager, Bartłomiej Lesiuk, said: “With this logistics automation project, production, the warehouse and dispatch will be automatically connected.”

“We’ve opted for a modular design that gives us the flexibility to adapt as our needs evolve.”

Join 400 exhibitors and 10,000 industry leaders at Robotics and Automation Exhibition on 18-19 March 2026 at NEC Birmingham to explore cutting-edge technologies, connect with peers and discover the latest innovations shaping the future of manufacturing, engineering and logistics. Register for free now to secure your place at this unmissable event!